New Biogas Boiler: More Than a Boilerplate Solution

2022 Engineering Excellence Best of State

![]()

Entering Firm: Donohue & Associates Inc.

Client: City of Appleton

The Appleton Wastewater Treatment Plant is an environmentally sustainable facility. It treats over five billion gallons of wastewater annually and two large anerobic digesters create biogas for heating. However, the biogas varied in concentration and was inefficient to use. The facility looked for a way to improve and become more sustainable.

Adding Consistency to the Mix

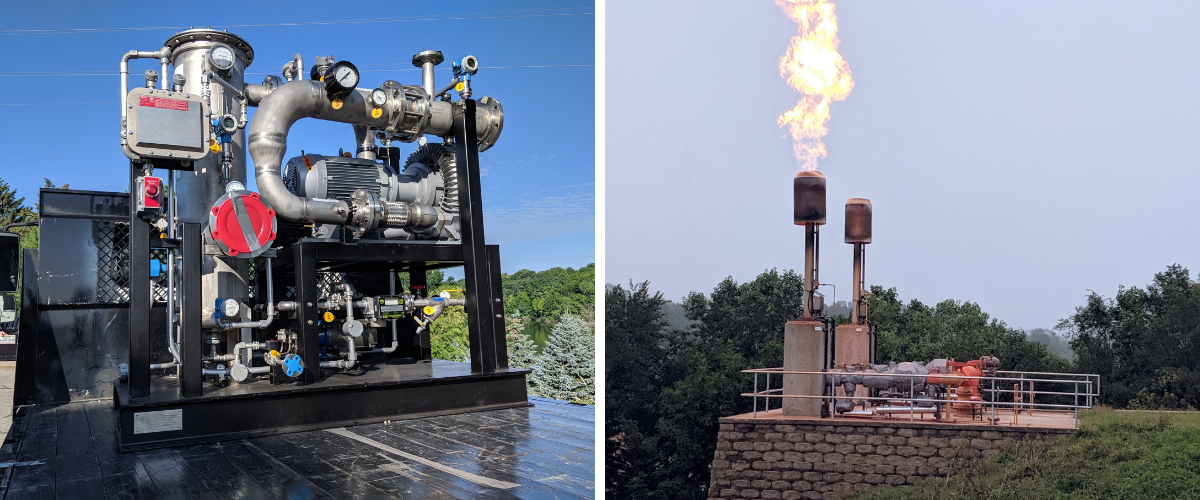

Donohue & Associates has extensive experience with biogas. After reviewing the system, the team determined a new optimization process was needed. Previously, the biogas was pushed directly from the digesters to the boilers. Now, the gas goes from the digesters to a stabilization tank which homogenizes the gas. A condensate trap in the stabilization tank draws out moisture, improving the quality of the gas. The biogas is then pulled into a compressor that increases its potency and then is finally fed to the boilers.

The new system delivers a consistent high-quality product to the boilers. The new system did not require major facility expansion and meets the client’s goal of environmental sustainability. By running at peak efficiency, the boilers save $100,000 annually.

Awards judge Tom Buchholz said, “Donohue designed a new 5.5 million BTU biogas boiler, biogas compression system to feed the three boilers, controls, stainless steel piping, and re-configured the biogas storage vessel piping for a flow-through design. This is the first time this technology has been used in Wisconsin and came in 12 percent under budget. Nice job”.

Exceeding Client Expectations

Using their years of experience, the design team developed a cost-effective solution that saves money and continues Appleton’s goal of environmental sustainability.